Next-Generation Automotive Manufacturing Materials and Processes

Over the past decade the automotive industry has seen massive changes in next-generation automotive manufacturing materials and processes. Vehicles of the past consisted of entirely steel-based products, while modern auto manufacturers are transitioning towards aluminum, magnesium, and composite materials that deliver enhanced performance. To accommodate for these new materials, new manufacturing techniques are also being adopted. This article will take a look at upcoming processes and material changes the automotive industry will be moving towards over the next 20 years.

This article is the 2nd of a 3-part series on automotive trends:

- Part 1: Intelligent Mobility

- Part 2: Manufacturing Materials and Processes

- Part 3: Alternative Vehicle Propulsion Systems

As identified by the Center for Automotive Research’s (CAR) Technology Roadmaps report, these are some of As identified by the Center for Automotive Research’s (CAR) Technology Roadmaps report, some of the most important automotive manufacturing trends to watch in coming years, including new automotive materials, innovative parts manufacturing, and automated assembly processes, will quickly re-define how the automotive supplier industry operates.

Canadian automotive manufactures that are looking to adopt new technologies and processes into their plants can utilize Canadian government grant, loan, and tax credit programs for auto manufacturers to help subsidize the cost of these strategic growth projects.

However, there is some uncertainty in the automotive industry that could change how quickly these advanced vehicle technologies become market standard. New materials must be safe, cost-efficient, and commercialized if they are likely to be used for more vehicle components. To achieve these production standards, the manufacturing process itself must be improved first.

What are the Most Commonly Used Automotive Materials?

CAR’s Technology Roadmaps report identifies current materials and manufacturing technologies used in 42 vehicles, covering four vehicle segments (cars, CUV, SUV, light trucks) from model year 2015/2016. The 42 models sampled represent approximately 50% of light-duty vehicle sales in the U.S.

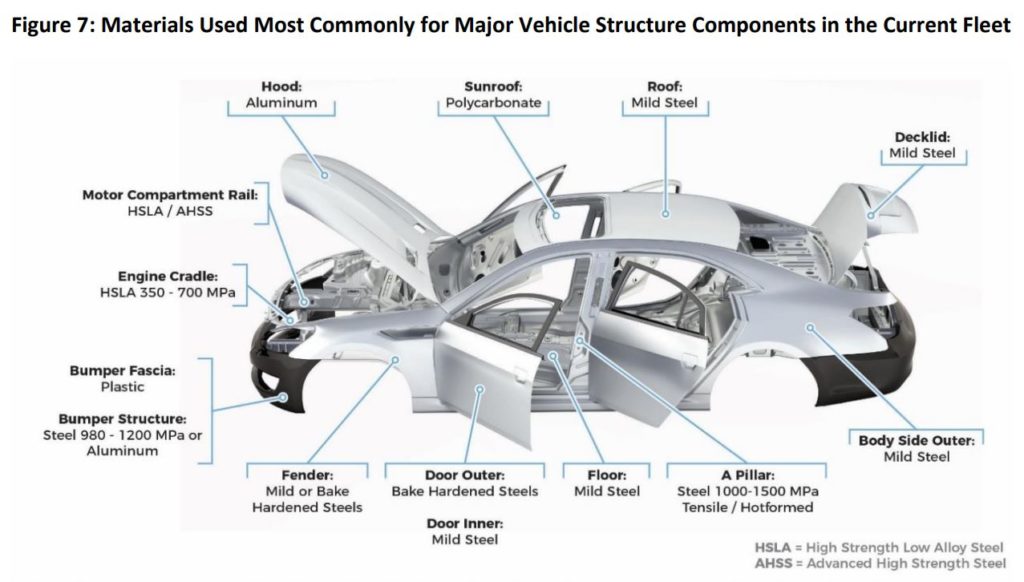

Unsurprisingly, the study found that current vehicles are predominantly steel structures with some use of aluminum. Vehicle frames, including floors, doors, roofs, body side panels, and fenders are all typically constructed from steel. As these are the components most responsible for driver safety, they are the most difficult to use other materials for. Materials used for other less-critical components such as a vehicle’s hood, sunroof, bumper, or engine cradle are often experimented with as they offer opportunity to reduce overall vehicle weight.

Today, and into the foreseeable future, the most commonly used automotive materials include:

- Mild Steel: Mild steels are easy to form, which makes them a top choice for automotive parts manufacturers using cold stamping and other dated manufacturing processes. They have a maximum tensile strength of 270 MPa.

- High Strength Steel (HSS): High strength steels use traditional steels and remove carbon during the baking cycle. This means softer steels can be formed and then baked into harder metals. Typical tensile strength grades range from 250 to 550 MPa.

- High Strength Low Alloy (HSLA): HLSAs are carbon manganese steels strengthened with the addition of a micro alloying element such as titanium, vanadium, or niobium. These have a tensile strength up to 800 MPa and can still be press formed.

- Advanced High Strength Steel (AHSS): Advanced high strength steels generally yield strength levels in excess of 550 MPa. They are composites made of multiple metals, then heated and cooled throughout the manufacturing process to meet a part’s specifications.

- Ultra High Strength Steel (UHSS): These follow similar properties as AHSS but maintain strength levels of at least 780MPa.

- Boron/Martensite: Martensite is the hardest and strongest form of steel, but it’s also the least formable. It shares properties with boron, which has a tensile strength of around 1,200 to 1,800 MPa. These are usually combined with softer steels to form composites.

- Aluminum 5000/6000 (AL 5000/6000): 5000-series aluminum is alloyed with magnesium. 6000-series aluminum contains both silicon and magnesium which forms magnesium silicide and makes the aluminum alloy heat-treatable.

- Magnesium: Magnesium is an attractive material for automotive use because of its light weight. When alloyed, magnesium has the highest strength-to-weight ratio of all structural metals.

- Carbon Fiber Reinforced Plastic (CFRP): CFRPs are extremely strong, light plastics which contain carbon fibers to increase strength. They are expensive to produce but will have a growing demand in the future automotive industry as costs are reduced.

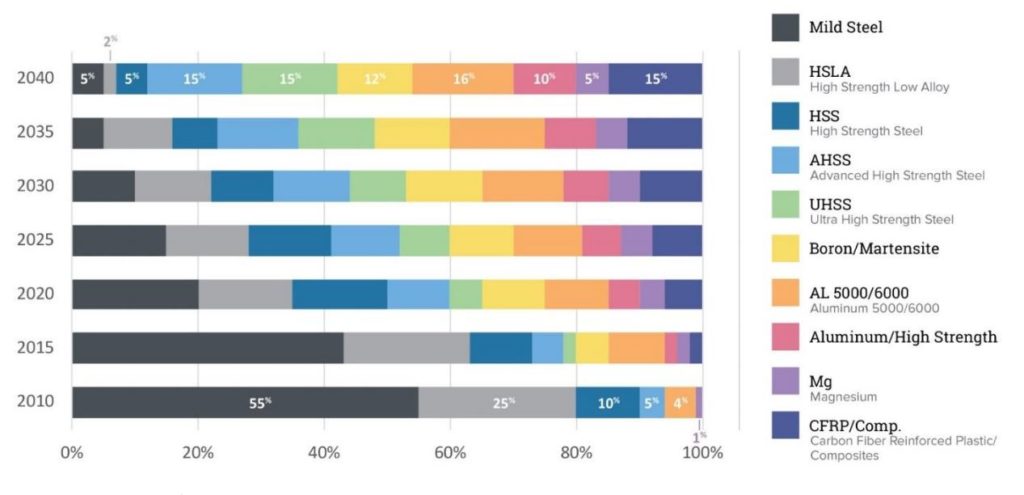

As depicted above, the composition of vehicles is quickly changing and becoming incredibly diverse. In the 10-year period of 2020 to 2030, mild steel use will be cut in half and will be replaced with higher-strength steels, aluminums, and composites. This trend will continue to unfold well into the future as automotive materials become more advanced and cost-competitive with traditional steels.

Innovative Methods of Automotive Parts Manufacturing

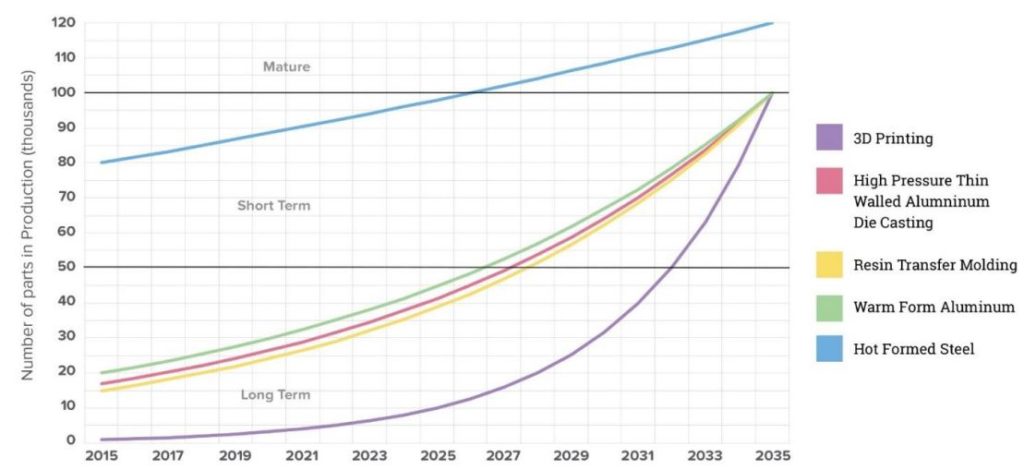

Cold-formed steel is still the industry standard for manufacturing automotive parts, but as detailed in the innovative materials above, high-strength materials are the future. High strength steels are difficult to cold form, which has led to the recent rise of hot forming or hot stamping, where stronger, thinner, lighter components may be developed.

Some of the innovative manufacturing processes that will redefine automotive parts include:

- Hot Formed Steel: Increasing the heat of steel improves ductility and helps form complex shapes without cracking.

- Warm Formed Aluminum: Aluminums require less heat but follow a similar logic to heating steel. Aluminum is warmed and formed at approximately 200-300 degrees Celsius to improve flexibility, then is cooled to increase strength.

- High Pressure Thin Walled Aluminum Die Casting: Aluminum’s high melting and solidifying temperature points mean that thin aluminum molds need to be filled quickly before temperatures cool. This creates the need for high heat, high pressure manufacturing processes.

- Resin Transfer Molding: Resins are pumped at high pressure into molds where they meet a pre-inserted fibre-preform. This transforms light preform materials into high-strength automotive parts.

- 3D Printing: 3D printing offers manufacturers the opportunity to develop prototypes and full-scale parts that are significantly more complex than possible when forming or molding. Parts can be printed with a variety of mediums from high-strength plastics to aluminum and some stronger metals.

As cold forming and traditional pressing/molding applications become less popular, it will give rise to the newer, more innovative technologies introduced above. Hot forming is currently the most popular and will continue to surpass other automotive manufacturing methods because of its ability to create stronger and lighter steels.

Automotive Assembly Processes: Present and Future

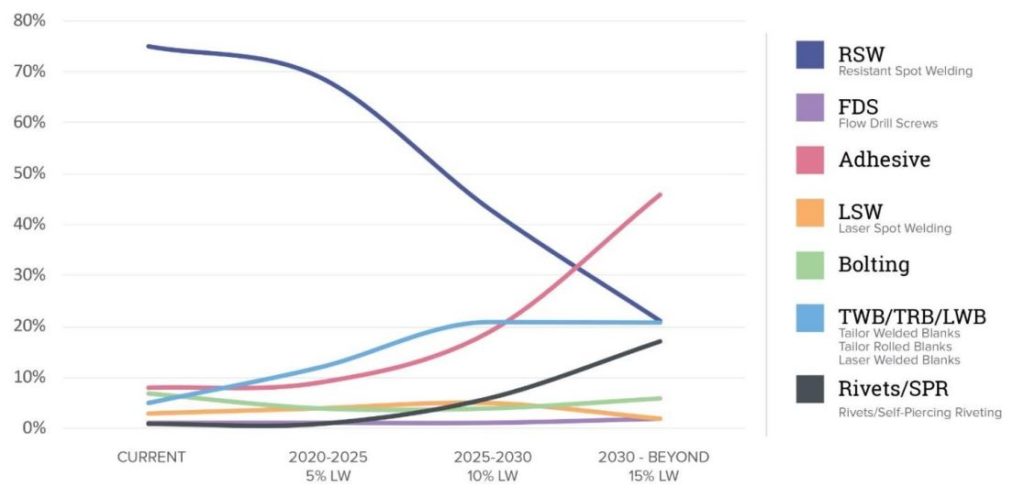

Manual and automated spot welding joins contacting metal surfaces with extreme heats generated by electric current. This has been the standard way to join steel for decades in the automotive industry, but will be ineffective with the integration of non-metal based parts.

Automotive assemblers must look for new options in the future that can join multiple types of materials together. Some include:

- Adhesives: Contains a wide range of glue-type substances that can currently join carpet, windshields, etc. but will soon have additional applications as an increase in plastic parts is expected.

- Tailor Welded/Rolled Blanks and Laser Welded Blanks (TWB/TRB/LWB): Combines several grades, thicknesses, and coatings of steel to place the best material in the best places.

- Rivets/Self-Piercing Riveting (SPR): Uses a high-speed mechanical fastening process for point joining sheet material, typically steels and aluminum alloys.

- Bolting: Uses pre-drilled holes to insert a bolt and nut which can be tightened and locked to bring two similar or dissimilar materials together.

- Laser Spot Welding (LSW): Uses advanced laser systems to create a weld spot which fuses metals to a rigid connection.

- Flow Drill Screws (FDS): Uses self-piercing and extruding fastener for joining layers of sheet metal. This combines the properties of friction drilling and thread forming, as the screw acts as both a fastener and a drilling-and-tapping tool.

Already in decline, spot welding will be quickly overtaken in popularity through specialized adhesives which can join plastic and metal parts as efficiently as possible. Welded blanks and riveting could also become one of the most prominent assembly techniques as new materials are introduced.

How Will Automotive Manufacturing Materials and Processes Evolve?

The automotive manufacturing timelines or “roadmaps” provided in CAR’s report are a calculated look at the future based on current materials and process trends. While predictions can never be made with complete accuracy, they offer a calculated approach that accounts for technological and cost competitiveness hurdles.

Each innovative manufacturing technology and material has factors that could impact predicted timelines. Depending on these factors, widespread industry adoption could either be accelerated or postponed.

Enabling Factors

- Fuel Economy: Lighter materials will lead to lighter vehicles that require less fuel for propulsion. Fuel economy is an attractive selling feature for customers, so automakers will try to satisfy this demand.

- Vehicle Emission Reduction: Legislative requirements may force automotive manufacturers to improve fuel economy as a means to lower greenhouse gas (GHG) emissions.

- Autonomous Vehicles: Self-driving vehicles have significantly more components than driver-required vehicles. This extra weight and space needs to be offset through the lightening of the other parts.

- Electric Powertrain: Electric engines and batteries weigh more than modern internal combustion engines. The switch to electric powertrains requires other materials to be lighter to compensate.

- Added Content: Drivers expect improved vehicle features each model year. To do this, components need to become lighter over time or else fuel economy will suffer.

Threatening Factors

- Mixed Material Joining: Differences in melting points between materials means that traditional welding techniques must be innovated.

- Corrosion: Exposure to moisture can break down new materials over time, causing failure of vehicle systems.

- Thermal Expansion: As parts enter paint ovens, parts made of some materials may expand or be coated differently than other materials.

- Cycle Time: Parts made of innovative materials need to be manufactured at a similar speed as traditional techniques to ensure a similar throughput.

- Cost: New materials such as carbon fiber can cost significantly more than traditional materials.

- Supply Chain: Manufacturers across the world must be able to source materials and maintain the equipment to process it. More complex materials are difficult to reproduce across the world, leading to supply chain disruptions.

- End-of-life Recycling: Automotive materials should be recyclable upon the retirement of a vehicle. Some advanced materials do not meet recycling requirements.

- Repair: Repair costs are higher with more complex materials, which increases cost of ownership including ongoing maintenance fees.

- Talent Gap: Engineers and manufacturing plant workers need to be trained on new complex materials and processes.

Find Canadian Government Grants for Automotive Manufacturers

The Canadian federal and provincial governments are frequently introducing new government funding grant, no-interest loan, and wage subsidy programs for Canadian automotive manufacturers. You can visit our directory of automotive manufacturer funding programs or contact Mentor Works to find out what funding programs your business may be eligible to receive. Mentor Works can write or review your application for government funding programs to ensure you have the best chance at being approved.

Find more information on Next-Generation Automotive Manufacturing Materials and Processes by downloading our free Canadian Automotive Trends PDF to learn how your business can capitalize on current trends and take advantage of government funding.

Dear Team,

Thanks for sharing. I would like to here more about the Materials and Processes in future for Commercial Truck industry in North America.

Thanks,

Girish Ramdasi

Hi Girish,

Thank you for your comment. We will make a note of this and add the topic to our future blogs.